The main advantage of plastics is their durability, and this also makes them the biggest problem. In the past, scientists tried to produce materials that could replace plastics and at the same time be economically advantageous to produce. Now, an alternative has finally been made that could replace plastics made from petroleum.

Scientists from EPFL (Laboratory for Processing of Advanced Composites) have developed a new, PET-like plastic that is easily made from the non-edible parts of plants. When ordinary plastic gets into nature, it will not decompose here and will contaminate it. The newly developed bioplastic behaves differently, it can be chemically easily recycled and decomposed into harmless sugars.

Quality bioplastic made from biomass

Plastic is popular because of its low purchase price, and for companies around the world to start using its alternative, it needs to be economically beneficial for them. There are considerable efforts to develop degradable or recyclable polymers made from non-edible plant material referred to as “lignocellulosic biomass”. Scientists led by Professor Jeremy Luterbacher at EPFL’s School of Basic Sciences have successfully developed a biomass-derived plastic, similar to PET. This new material could replace plastics in the future.

“We essentially just ‘cook’ wood or other non-edible plant material, such as agricultural waste, in inexpensive chemicals to produce the plastic precursor in one step,” says Luterbacher. “By keeping the sugar structure intact within the molecular structure of the plastic, the chemistry is much simpler than current alternatives.”

This new type of plastic is based on a discovery that Luterbacher and his colleagues published back in 2016. However, they have now greatly improved this method.

“By using a different aldehyde – glyoxylic acid instead of formaldehyde – we could simply clip ‘sticky’ groups onto both sides of the sugar molecules, which then allows them to act as plastic building blocks,” says Lorenz Manker, the study’s first author. “By using this simple technique, we are able to convert up to 25% of the weight of agricultural waste, or 95% of purified sugar, into plastic.”

How can bioplastics be used?

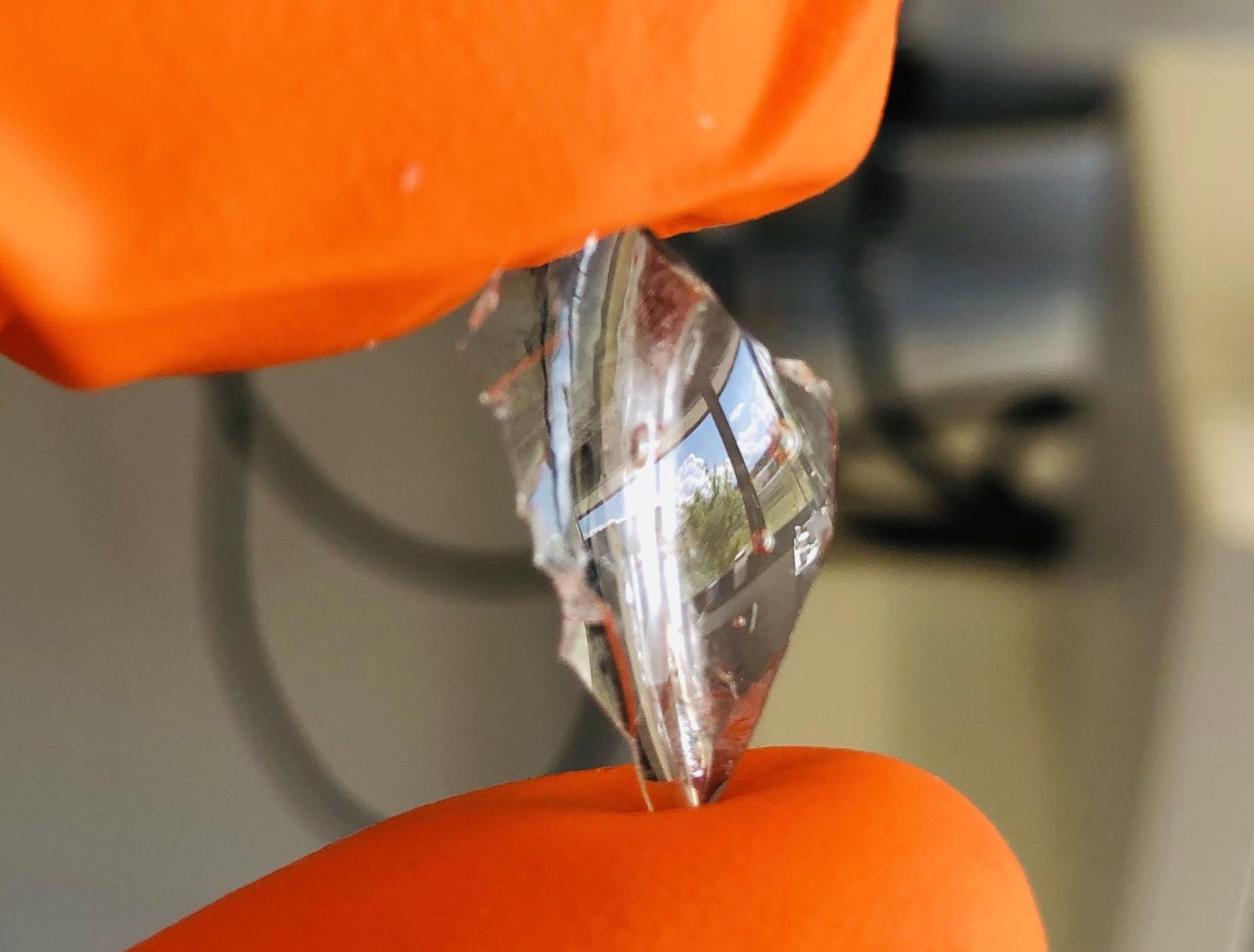

Due to their properties, bioplastics have a wide range of uses. They could be used as food packaging, they will also find use in the textile industry, but also in electronics. Scientists have already successfully produced packaging films, fibers for the production of clothing and fibers that could be used in 3D printers from bioplastic.

“The plastic has very exciting properties, notably for applications like food packaging,” says Luterbacher. “And what makes the plastic unique is the presence of the intact sugar structure. This makes it incredibly easy to make because you don’t have to modify what nature gives you, and simple to degrade because it can go back to a molecule that is already abundant in nature.”

Source: https://actu.epfl.ch/news/new-pet-like-plastic-made-directly-from-waste-biom/

Credit: EPFL, Lorenz Manker